As a result of cytotoxicity and/or poor net yields,

microbial biofuels may typically only accumulate to low final concentrations in

culture media. Their efficient, rapid, and thorough recovery from the culture

medium is a universal challenge to the biotechnology industry. Solid-phase

adsorption is commonly employed to provide high efficiency separations of

microbial products from culture media. However, traditional chromatographic

applications are poorly compatible with the in situ recovery of biofuels.

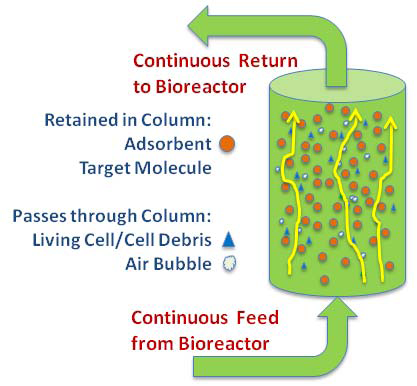

Researchers at Arizona State University have developed a

novel, expanded bed adsorption and elution process for the recovery of biofuel

products or precursors from cell culture medium. This is accomplished via an in

situ and biocompatible approach to enable high and continuous productivity.

Separation can be achieved in a manner that does not disrupt cell growth,

precludes the use of special cell separation equipment, and requires only

minimal energetic input.

Potential Applications

- Recovery and purification of:

Benefits and Advantages

- Biocompatible - achieves separation in a manner

supporting continued cell growth and productivity

- Economical - a low energy and low cost process

- In situ - relieves product inhibition and/or reduce

contamination through continuous product removal

- Adaptable – adsorbent can be easily substituted to meet

specific separation needs

- Scalable – can be sized to meet process requirements

- Modular – External process design amenable to retrofit

applications

- Increases interstitial spacing between adsorbent

particles resulting in lower required pressure drop

Download Original PDF

For more information about the inventor(s) and their

research, please see

Dr. Nielsen's laboratory webpage